Hi friends! In this article, we will learn about a good profitable small industry idea nowadays.

Innovation in the manufacture of AAC blocks i.e. autoclave aerated concrete blocks is a major breakthrough in the construction industry. Positive features such as being able to withstand climate change as well as being light weight and heat tolerant. AAC blocks have become very popular in building construction in recent times. So this AAC block manufacturing industry can be a good self employment path for you.

Now let us know what are the raw materials required for the manufacture of these AAC blocks.

Fayash (thermal power plant waste), lime powder, cement, gypsum, aluminum powder.

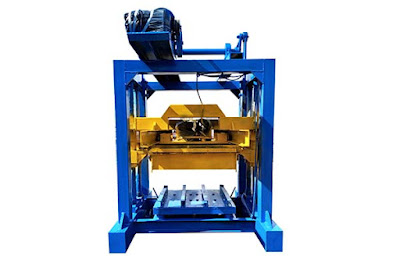

Now let us know what are the machines required for the manufacture of these AAC blocks.

1) Mixing machine. It is priced at Rs. Starting from the 18000s

2) Cutting machine. It is priced at Rs. Starting at 1,60,000

3) Autoclave machine. It is priced at Rs. Starting at 5,00,000.

The prices of these machines fluctuate depending on their production and capacity.

Manufacture of AAC blocks:

The raw materials are mixed well to a certain size and poured into large size molds. The slightly hardened generation air is cut with a special machine to the required sizes. These blocks are then dehumidified by steam cooking for 10-12 hours in an autoclave machine. The blocks taken from the autoclave are moved to the cooled generation storage area and then sent to the market.

Different sizes of AAC blocks:

These are usually made in three sizes.

24x8x4 inches • Each block weighs 8 – 9.5 kg

24x8x6 inches బ్లాక్ Each block weighs 9.5 – 11.5 kg

24x8x8 inches • Each block weighs 13.5 – 15.0 kg

The size blocks per cubic meter come in 83, 56, 42 respectively.

Now let us know what are the benefits due to AAC blocks.

Waste is being utilized due to the use of fiash in thermal power plants.

ఎ AAC blocks have all the positive features required for building. So they are an alternative to clay bricks and concrete blocks.

Less weight, less time, more construction possible with fewer workers. It is also advantageous that this block size is large. A reduction of 30-35% in construction cost is possible with the use of these blocks.

Market for AAC blocks:

These blocks are widely used in commercial and industrial buildings, government and private offices, apartments and gated community structures. Industry groups estimate that the use of AAC blocks will grow by 20-25% each year.

Government permission:

We need government permission for our business:

Must register under MSME udyog aadhar scheme.

Taking permission from local authorities.

Also state pollution board certificate can be taken.

Trade license permission can also be obtained.

Subsidy:

We have subsidy schemes:

15-35% subsidy can be availed under PM Employment Innovation Scheme (PMEGP). 90% loan can also be obtained.

Also Technology and quality upgradation support for MSME members and

Credit linked capital subsidy scheme for technology upgradation (CLCSS).

Thus we have subsidy schemes available. Contact your nearest District Industries Center for more details.